- GS Housing packaged container houses are factory-prefabricated, featuring rapid installation, flexible mobility, and eco-friendly performance. They are widely used in oilfield camps, mining projects, temporary offices, emergency housing, and multifunctional buildings.

- Tailored to your project – choose from flexible layouts, and sizes, all with the speed and efficiency of modular container house steel construction.

- Certifications: ISO / CE / ASTM / SGS / SASO / GOST-R / UL / BUREAU VERITAS

GS Housing modular container units offer distinct advantages including factory prefabrication, rapid installation, high mobility, and energy efficiency with environmental benefits. They are widely applicable for oilfield camps, mining projects, temporary offices, emergency accommodation, commercial buildings, and multi-purpose space construction.

Rapid Deployment, Efficient Implementation

All units undergo standardised factory production, requiring only crane assembly on-site before becoming operational. This efficient construction method not only significantly reduces project timelines but also effectively mitigates disruptions from external factors such as weather and environmental conditions, making it particularly suitable for projects with tight schedules or complex site conditions.

Flexible Customisation to Meet Diverse Needs

Different projects present unique application scenarios and functional requirements. GS Housing offers bespoke customisation services, including exterior design, internal layout, material selection, and supporting facility configurations. Whether creating comfortable staff accommodation, fully-equipped office spaces, or comprehensive camps with public service facilities, solutions are tailored precisely to client specifications.

Quality Assurance for Long-Term Durability

Constructed with high-strength steel structures and eco-friendly electro-galvanised wall panels, units feature pre-embedded drainage piping around all sides. This delivers superior waterproofing, fire resistance, thermal insulation, and weather resistance. Rigorous production and quality control systems ensure enduring stability and durability throughout extended service life.

Green and Sustainable

Modular production significantly reduces construction waste and noise pollution. The units support multiple disassembly cycles and recycling, minimising resource wastage while reducing construction debris.

Whether for projects demanding efficient construction or spaces requiring flexible office and living layouts, GS Housing’s customisable container units deliver professional, reliable turnkey solutions. With our strengths in rapid deployment, flexible customisation, exceptional quality, and environmental sustainability, we remain committed to being your trusted modular building partner.

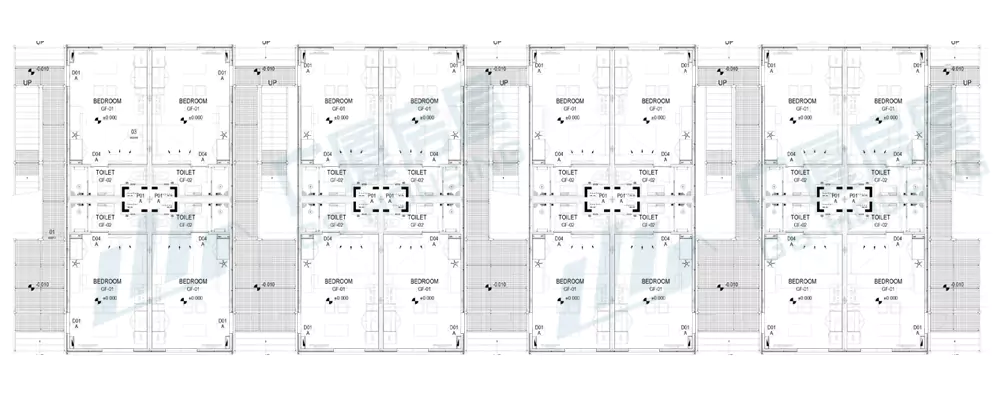

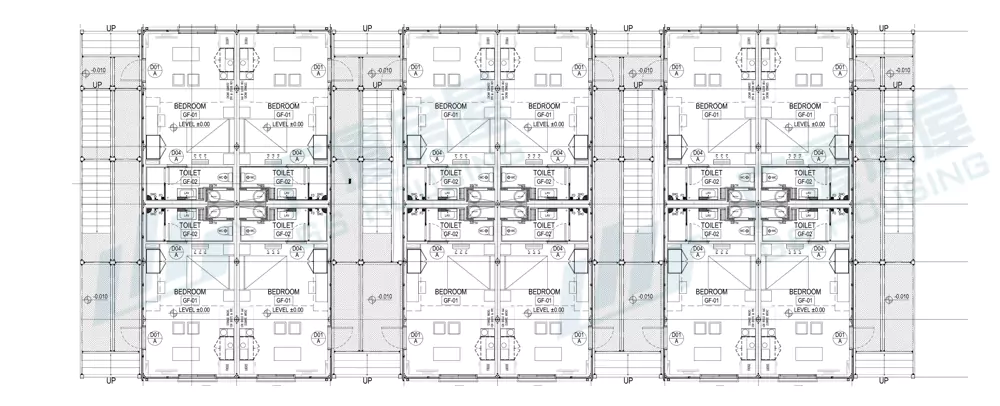

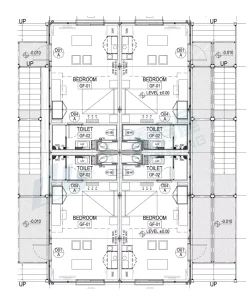

Design Drawings

|

|

|

Specifications

| NO. | NAME | SPECIFICATION |

| 1 | Main beam for the top frame | Material: Q355B,t=3.0mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 2 | Main beam for the bottom frame | Material: Q355B,t=3.5mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 3 | Column | Material: Q355B,t=4.0mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 4 | Secondary beam for the top frame | Material: Q355B,t=1.5mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 5 | Secondary beam for the bottom frame | Material: Q355B,t=2.0mm ,Galvanized cold roll steel,Galvanizing amount 275g/㎡ |

| 6 | Insulation material for the top and bottom frame | 100mm thick rock wool felt with aluminum foil on one side, bulk density ≥60kg/m³, combustion performance is Class A non-combustible; |

| 7 | External wall panels | 50mm thick color steel sandwich panel, with a 0.5mm corrugated galvanized color steel outer layer, a 0.5mm aluminum-zinc color steel inner layer, and rock wool density of 100kg/m³. |

| 8 | Inner wall panel | 70mm thick color steel sandwich panel, with a 0.5mm corrugated galvanized color steel outer layer, a 0.5mm aluminum-zinc color steel inner layer, and rock wool density of 80kg/m³. |

| 9 | Gypsum board | ordinary gypsum board 、 moisture-proof gypsum board、 fireproof gypsum board |

| 10 | Sloping roof | 0.5mm thick V-840 white-gray color steel tile, 2C KZ system, with a zinc coating of 275g/㎡; cornices and columns are made of 0.8mm color steel plate. |

| 11 | Door | Black, fireproof for 60 minutes, master key |

| 12 | Window | The glass is made of transparent low-emissivity 8lov-e+16A+6+0.76pvd+ coated low-transmittance tempered laminated insulating glass |

For more information, you can contact us.

| Product Advantages |

| Why Choose GS Housing |

| Authorative Certification |

| After-sales Service | |

| 1 | Do you provide on-site installation service? We provide very detailed installation instruction drawings and videos for every project.For large projects, we will have both installation workers and supervisors on site.The fee for the on-site service should be negotiated with clients. |

| 2 | What’s your delivery time? Normally, delivery time is 7-10 days after deposit received. For large order, the delivery time should be negotiated. |

| 3 | How to control the quality of your product? 1. quality of the design: think about possible problems in advance and provide a high-quality design solution. 2. quality of the raw material: choose the qualified raw material 3. quality of the production: precise manufacturing technique, experienced workers, strict qualit inspection. |

| 4 | How to deal with quality problems? Warranty is 1 years. Within the warranty period, GS Housing will responsible for all quality problems caused by our production. |

| 5 | If there is a clear service life of your products? If have,how long? Under conventional climate and environment, the service life of container house steel frame is 20 years |

| 6 | What designs do you have in different climates (How can the products adopt to different climates)? Strong wind region: improve the wind-resisting ability of the internal structure. Cold region: increase the thickness of the wall,or use good insulation material, improve anti-pressure ability of the structure. High corrosion region: use corrosion resistant material, or paint anti-corrosive coating. |

Leave Your Message

For more information, please fill out the form, and we will respond to you via email within 24 hours.