Análisis Profesional de MIC y DFMA para Expertos Avanzados en Construcción

Análisis Profesional de MIC y DFMA para Expertos Avanzados en Construcción

El mundo de la construcción está cambiando rápidamente. Nuevos métodos como la Construcción Integrada Modular (MIC) y el Diseño para la Fabricación y el Montaje (DFMA) están sacudiendo las cosas. Estos enfoques aportan precisión de fábrica, trabajo en el sitio más rápido y hábitos ecológicos a los proyectos de construcción. Este artículo se sumerge en cómo MIC y DFMA trabajan solos y juntos, destacando GS Viviendasoluciones inteligentes que combinan ambas ideas. Verás cómo las piezas prefabricadas, las piezas estándar y los diseños flexibles están haciendo que la construcción sea más rápida, más barata y mejor para hogares, hospitales o proyectos urbanos. Aprenda por qué los constructores eligen estas herramientas para abordar la escasez de trabajadores, los horarios apretados y los objetivos ecológicos mientras crean estructuras fuertes y de alta calidad.

¿Qué es la construcción modular integrada (MIC)?

¿Cuáles son los principios básicos del MIC?

Construcción Modular Integrada (MIC) Es un cambio de juego para la construcción. Significa fabricar piezas de construcción en fábricas limpias y controladas antes de trasladarlas al sitio para una instalación rápida. Este método se centra en diseños estándar y elaboración cuidadosa. Cada módulo está construido para ser de primera clase antes de salir de la fábrica. Estas unidades a menudo vienen con sistemas incorporados como tuberías, alambres e incluso acabados de pared. MIC apoya la construcción verde, el trabajo rápido y los diseños flexibles para resolver los problemas de construcción de hoy en día.

¿Por qué MIC es útil para los proyectos de hoy?

¿Cómo aumenta la prefabricación la velocidad?

La prefabricación en MIC hace que los proyectos se muevan más rápido. Las fábricas utilizan herramientas y máquinas de alta tecnología para construir piezas, manteniendo la calidad constante. Esto reduce el trabajo en el sitio y evita retrasos por mal tiempo o problemas de entrega. Las fábricas también revisan cada pieza de cerca para asegurarse de que es perfecta.

¿Reduce el MIC el tiempo y los trabajadores en el sitio?

Sí, MIC brilla aquí. Al trasladar la mayoría del trabajo a las fábricas, necesita menos trabajadores en el sitio. Esto acelera los proyectos y reduce los riesgos como los accidentes. Además, mantiene los sitios más limpios y silenciosos, con menos basura y ruido.

¿Qué es Diseño para fabricación y montaje (DFMA)?

¿Qué hace que DFMA sea especial en la construcción?

El diseño para la fabricación y el montaje (DFMA) es una forma inteligente de planificar piezas de edificios. Se centra en hacer piezas fáciles de construir y montar. En la construcción, DFMA simplifica los diseños para que el trabajo de fábrica sea suave y la configuración del sitio sea sencilla, todo ello manteniendo las cosas funcionales.

¿Cómo DFMA Mejora los Proyectos?

¿Cómo Easy Assembly ahorra dinero?

DFMA mantiene los diseños sencillos para reducir los costos. Las piezas estándar son más baratas de fabricar en grandes cantidades, ahorrando tiempo y materiales. Además, las piezas fáciles de montar reducen el tiempo de trabajo en el sitio. Esto ayuda a mantener los presupuestos bajo control sin perder calidad.

¿Puede DFMA mejorar los controles de calidad?

Sí, por supuesto. DFMA planea que las piezas sean bien hechas en fábricas. Esto detecta los errores temprano, antes de que las piezas lleguen al sitio. Piezas de alta calidad significan edificios más fuertes que duran más tiempo.

¿Cómo difieren MIC y DFMA?

¿Se centran en construir o combinar piezas?

MIC y DFMA tienen como objetivo mejorar la construcción, pero se centran en cosas diferentes. MIC se trata de combinar secciones completas de edificios listas para usar. DFMA, sin embargo, trabaja en hacer que cada pieza sea fácil de construir y encajar.

¿Su diseño se basa en estándares o módulos?

MIC se basa en la modularidad. Crea trozos completos de edificio que pueden mezclarse y combinarse para diferentes proyectos. DFMA, sin embargo, se adhiere a la estandarización de las partes para mantenerlas sencillas y útiles de muchas maneras.

¿Cómo cambian las etapas del proyecto desde el diseño a la configuración?

MIC traslada la mayoría del trabajo a las fábricas, reduciendo el impacto del sitio y acelerando las cosas. DFMA se centra en el diseño inteligente desde el principio, haciendo que el cambio de fábrica a sitio sea suave y sencillo.

Para los constructores que exploran estos métodos modernos, herramientas como GS Housing dan grandes ideas para la construcción modular adaptada a muchos tipos de proyectos.

Integración GS Vivienda Productos con enfoques MIC y DFMA

Las soluciones modulares de GS Housing combinan los trucos de construcción rápida de MIC con el cuidadoso diseño de DFMA, ofreciendo una configuración rápida, prácticas ecológicas y ahorros de costos a través de piezas estándar y diseños adaptables.

Cómo son GS Vivienda ¿Soluciones vinculadas a los principios MIC?

Módulos prefabricados para una configuración suave del sitio

GS Housing es excelente en la fabricación de módulos preconstruidos que facilitan el trabajo en el sitio. Sus fábricas utilizan herramientas de primera clase para elaborar cada módulo a medida exacta. Estas unidades vienen listas con tuberías, alambres y acabados, por lo que son buenos para ir cuando lleguen. Esto encaja perfectamente con el enfoque de MIC en velocidad y precisión.

Además, el enfoque de GS Housing ayuda al planeta. El trabajo en fábrica reduce los residuos en el sitio, y el uso inteligente de materiales reduce las cosas adicionales. Estos pasos aumentan la velocidad del proyecto y apoyan los objetivos de construcción ecológica.

Diseños flexibles para necesidades modulares

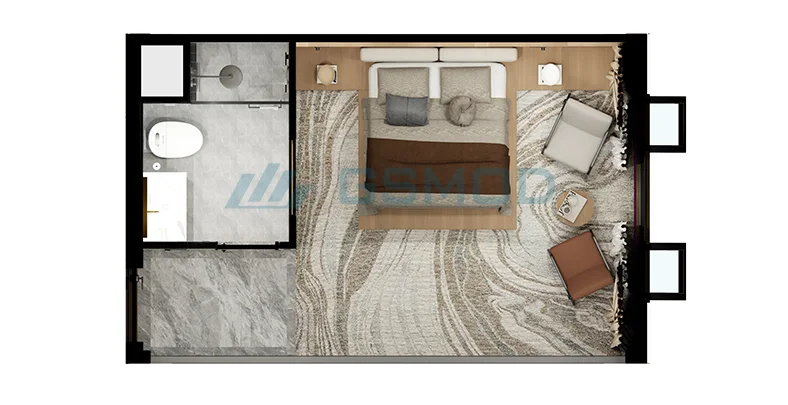

Los productos de GS Housing son súper flexibles. Puede cambiar el tamaño y el diseño de los módulos para adaptarse a diferentes proyectos. Ya se trate de hogares, oficinas o lugares especiales como hospitales o escuelas, GS Housing crea módulos que funcionan. En espacios urbanos estrechos, sus diseños pueden combinar tiendas, oficinas y áreas divertidas en una configuración inteligente. Esta flexibilidad ayuda a los proyectos a satisfacer las necesidades de hoy y a crecer más tarde con poco alboroto.

Cómo hacer GS Vivienda Tecnologías ¿Apoyan las estrategias de DFMA?

Edificio de alta tecnología para un montaje perfecto

GS Housing utiliza las ideas de DFMA confiando en herramientas avanzadas de fábrica. Se aseguran de que cada pieza está hecha correctamente, reduciendo los errores durante la configuración del sitio. Esto mantiene la calidad alta y los proyectos en el buen camino.

El uso de piezas estándar también acelera las cosas y ahorra recursos. Los métodos cuidadosos de GS Housing se aseguran de que las piezas encajen bien, manteniendo los edificios fuertes y de buen aspecto.

Diseños sencillos para una instalación fácil

GS Housing diseña piezas para que sean fáciles de montar. Después de DFMA, sus piezas se fabrican para un montaje rápido en el sitio. Las piezas estándar son más baratas de producir, ahorrando tiempo y dinero. Este enfoque mantiene los presupuestos ajustados al tiempo que garantiza la máxima calidad.

Además, el enfoque de GS Housing en la modularidad significa que las piezas encajan perfectamente en la estructura más grande. Esto evita retrasos por piezas incompatibles o configuraciones complicadas. Ya sea empezar nuevos o actualizar edificios antiguos, los diseños de GS Housing hacen que las cosas sean eficientes.

Recomendaciones para el uso de MIC y DFMA en proyectos de construcción avanzados

¿Cómo elegir el método adecuado para su proyecto?

La elección entre MIC y DFMA depende de las necesidades de su proyecto. Si desea construir rápidamente con menos trabajo en el sitio, los módulos prefabricados de MIC son el camino a seguir. Si necesita piezas rentables y de alta calidad, los diseños sencillos de DFMA son los mejores.

Para grandes proyectos con muchos tipos de edificios, como hospitales o sitios de uso mixto, GS Housing es una gran opción. Sus habilidades cubren tanto MIC como DFMA, ayudándole alcanzar tus objetivos sin sacrificar la calidad ni la velocidad.

Por qué usar GS Vivienda ¿Productos para mejorar la eficiencia y la calidad?

Utilizar los productos de GS Housing significa aprovechar soluciones inteligentes que mezclan las fortalezas de MIC y DFMA. MIC se ha demostrado en la construcción de hospitales, escuelas y más porque es rápido y adaptable. DFMA, integrado en el trabajo de GS Housing, garantiza producción simplificada y fácil montaje.

Descubre cómo GS Housing puede cambiar tus proyectos con herramientas modulares de vanguardia y prácticas ecológicas para todo tipo de necesidades de construcción.

FAQs

Q1: ¿Puede MIC trabajar para la actualización de edificios antiguos?

R: Sí, MIC es principalmente para nuevos proyectos, pero se puede adaptar para la actualización de estructuras antiguas mediante el diseño de módulos para adaptarse a los espacios existentes.

Q2: ¿Cómo ayuda DFMA con la construcción ecológica?

R: DFMA reduce los residuos utilizando piezas estándar y métodos de producción inteligentes. Esto apoya los objetivos verdes mediante la reducción del daño ambiental.

Q3: ¿Qué proyectos obtienen más de la mezcla de MIC y DFMA?

R: Los grandes proyectos como hospitales o edificios de uso mixto se benefician mucho. Necesitan velocidad, flexibilidad y alta calidad, que MIC y DFMA ofrecen juntos.

Anterior:Consideraciones clave para garantizar la seguridad en los campos de trabajo

Siguiente:Análisis de costos de oficinas portátiles: una visión general completa

Contenido relacionado

-

-

Noticias de la industriaConstrucción Modular Integrada (MIC): Redefiniendo Futuros Urbanos Sostenibles

Noticias de la industriaConstrucción Modular Integrada (MIC): Redefiniendo Futuros Urbanos Sostenibles -

Noticias de la industriaAnálisis Profesional de MIC y DFMA para Expertos Avanzados en Construcción

Noticias de la industriaAnálisis Profesional de MIC y DFMA para Expertos Avanzados en Construcción