Which Is Better for Remote Camps Modular Camp Buildings or Traditional Construction

Which Is Better for Remote Camps Modular Camp Buildings or Traditional Construction

Remote camps are never built in easy places. They sit in deserts, mountains, frozen zones, offshore platforms, or deep inside mining and energy fields. What matters most is not fancy design, but speed, safety, and reliability. Project owners often face one big question early on: should the camp be built with modular camp buildings or traditional construction?

This article breaks that question down from a practical angle. Using real project experience from GS Vivienda, it looks at time, cost, safety, and long-term use—without industry buzzwords or theory-heavy talk.

Why Do Remote Camps Need Faster and More Flexible Building Solutions?

Remote camp projects usually run on tight schedules. Equipment arrives on a fixed date, workers rotate in large numbers, and delays can burn money fast. That reality has pushed many owners to rethink how camps are built. Before comparing methods, it helps to understand what these sites actually need.

Speed-Centric Construction for Time-Critical Projects

In oil & gas, mining, and pipeline projects, the camp is often the first thing that must be ready. Without housing, offices, clinics, and dining areas, work simply can’t start.

Traditional construction depends heavily on local labor, weather, and long on-site processes. In remote regions, all three are unpredictable. Modular camp buildings flip that logic. Most of the work is done in factories, while foundations are prepared on site at the same time.

GS Housing has delivered full camps for pipeline and LNG projects where thousands of workers had to move in quickly. In those cases, modular systems helped cut delivery time by months compared with brick-and-mortar methods.

Adaptable Layouts for Changing Worker Populations

Remote camps rarely stay the same size. A mining site may start with 200 workers, peak at 2,000, then scale back again. Traditional buildings are rigid. Once built, expansion or downsizing means demolition or new construction.

Modular camp buildings are easier to adjust, allowing for the addition, reduction or rearrangement of units. GS Housing often designs camps with expandable zones—extra dormitory blocks, stacked office units, or removable service buildings—so the camp can grow or shrink with the project.

Reduced On-Site Workforce and Safer Construction Environments

Remote sites are risky places to build. Long hours, extreme weather, and limited medical access increase safety concerns. Traditional construction needs large on-site teams for months.

With modular construction, on-site work is shorter and involves fewer people. GS Housing projects typically require only small installation crews for lifting and assembly. Fewer workers on site means fewer safety risks and easier site management.

How Do Modular Camp Buildings Improve Construction Efficiency in Remote Areas?

Efficiency is not just about speed. It also means predictable schedules, smoother logistics, and fewer surprises.

Factory-Based Production and Parallel On-Site Preparation

In traditional construction, everything happens in sequence: groundwork first, then structure, then interiors. Delays stack up easily.

Modular buildings work in parallel. While foundations are poured on site, GS Housing factories are already producing fully finished modules—walls, insulation, wiring, plumbing, even interior finishes. When modules arrive, assembly moves fast.

This approach has proven especially useful in GS Housing’s mining camps in Mongolia and Chile, where short building seasons leave little room for error.

Predictable Timelines With Weather-Independent Manufacturing

Weather is a major enemy of remote construction. Rain, snow, wind, or heat can shut down work for weeks.

Factory production avoids that risk. GS Housing manufactures modules indoors under controlled conditions, so rainstorms or sandstorms don’t stop progress. Project timelines become easier to plan, which matters a lot when equipment rentals and workforce logistics are involved.

Streamlined Logistics Using Flat Pack Container Houses

Transporting buildings to remote sites is often harder than building them. Narrow roads, long distances, and limited ports create real problems.

GS Vivienda casas de contenedores de paquete plano are designed with logistics in mind. Components are packed efficiently, shipped in standard containers, and assembled on site. Compared with shipping traditional materials piece by piece, this cuts transport trips and lowers risk of damage.

What Makes Modular Camp Buildings More Cost-Effective Than Traditional Methods?

Cost is not just the initial price tag. In remote projects, delays, rework, and long-term use all affect the final bill.

Controlled Material Use and Reduced Waste

Traditional sites waste materials. Offcuts, weather damage, and poor storage are common. In factories, material use is tighter and repeatable.

GS Housing’s production lines are set up for standardized modules, which reduces waste significantly. Less waste means lower material costs and cleaner sites—important in environmentally sensitive areas.

Lower Labor Requirements and Faster Deployment

Skilled labor is expensive in remote areas. Housing workers, feeding them, and rotating shifts adds to the cost.

Modular camps need fewer on-site workers and shorter installation periods. GS Housing projects often complete camp setup in weeks instead of months, cutting labor and accommodation expenses during construction.

Reusable Flat Pack Units With High Residual Value

Traditional buildings are usually written off after the project ends. Modular buildings can be reused.

GS Housing flat pack units are designed for multiple assembly cycles. Camps can be dismantled, moved, and rebuilt at a new site. That reuse gives the buildings real residual value, which traditional construction rarely offers.

How Do Safety and Durability Compare Between Modular and Traditional Camp Construction?

There’s still a myth that modular buildings are temporary or weak. In reality, quality depends on design and standards, not construction method.

Certified Structural Strength and Long Service Life

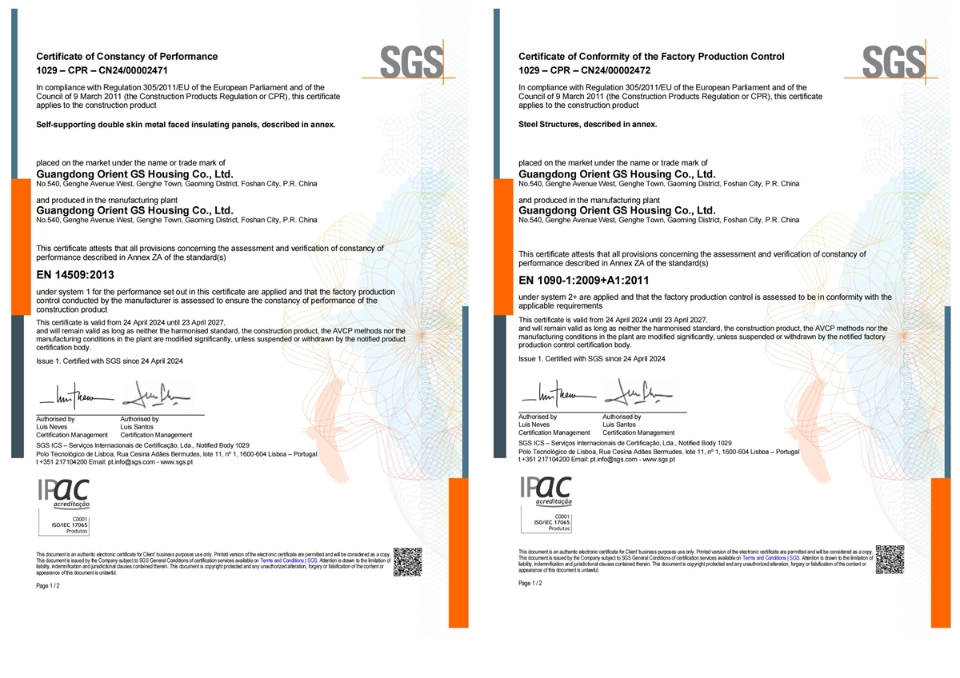

GS Housing modular systems are built with steel frames tested by national authorities. Many units are rated for strong wind loads and seismic conditions, making them suitable for harsh environments.

Service life often exceeds 20 years, which covers both temporary camps and semi-permanent facilities.

Fire-Resistant, Insulated, and Weather-Protected Systems

Remote camps often face strict safety rules, especially in oil, gas, and LNG projects. GS Housing uses non-combustible insulation materials and fire-rated wall systems. Thermal insulation helps camps operate in deserts and cold regions alike, improving worker comfort and reducing energy use.

Stable Quality From Factory Production Standards

On-site quality varies with workers and conditions. Factory production is more consistent.

Each GS Housing module goes through fixed inspection steps before leaving the factory. That consistency is why many global mining and energy companies keep returning for repeat projects.

Where Do Modular Camp Buildings Offer Superior Adaptability for Remote Sites?

Flexibility is one of the strongest arguments for modular camps.

Multi-Scenario Applications Across Mining, Oil & Gas, and Defense

GS Housing has delivered camps for mining operations, pipeline projects, LNG plants, and defense facilities. The same modular system can support dormitories, offices, clinics, kitchens, and warehouses.

This cross-industry use proves that modular camps are not niche products—they are adaptable systems.

Flexible Stacking and Combination With Flat Pack Container Houses

Modules can be stacked vertically or linked horizontally. GS Housing often combines flat pack container houses into multi-story blocks, saving land and improving layout efficiency. This is useful in tight sites like offshore bases or mountainous regions.

Easy Relocation for Shifting Camp Locations

Some projects are relocated every year, but traditional buildings struggle to keep up, while modular camps can. GS Housing has supplied mobile camps for pipeline routes where buildings move along with construction progress. That mobility saves both time and money.

Why Are GS Housing Modular Solutions Ideal for Remote Camp Projects?

Not all modular suppliers are the same. Capacity, experience, and system depth matter.

High-Capacity Factories and Consistent National Supply

GS Housing operates six large factories across China, with an annual capacity of around 200,000 modular units. This scale allows stable supply for large or multi-phase projects.

For overseas projects, consistent production standards across factories reduce risk and simplify planning.

Full Camp Solutions From Accommodation to Offices

GS Housing does more than sell boxes. It delivers full camp systems—housing, offices, clinics, dining halls, storage, and utilities planning.

This turnkey approach is especially valuable in remote locations where coordination is hard.

Proven Performance in Global Remote Camp Projects

From disaster relief camps in China to mining camps in South America and energy projects in Africa and Central Asia, GS Housing has real field experience.

Get a Customized Modular Camp Solution for Your Project

Every remote camp is different. Climate, workforce size, transport routes, and local rules all shape the final solution. Modular camp buildings offer a practical way to handle those variables without losing control over time and cost.

For project owners who value speed, safety, and flexibility, modular construction—especially systems like GS Housing’s flat pack container houses—has become the smarter choice in remote environments. If you have the need for modular camps, please contact GS Housing.

Preguntas frecuentes

Q1: Are modular camp buildings suitable for long-term use?

A: Yes. Many GS Housing camps are designed for 20+ years of service and can function as permanent or semi-permanent facilities.

Q2: How fast can a modular camp be installed on site?

A: Depending on size, installation can take weeks instead of months. Factory production and on-site preparation run at the same time.

Q3: Can modular camps meet international safety standards?

A: They can. GS Housing systems use certified steel structures, fire-resistant materials, and tested insulation, making them suitable for energy, mining, and defense projects worldwide.