Are Semi-Permanent Modular Camp Buildings the Smarter Choice for Remote Sites

Are Semi-Permanent Modular Camp Buildings the Smarter Choice for Remote Sites

Remote projects have their own rhythm. Whether you’re running a mining site, laying down oil pipelines, or supporting a large infrastructure build in a desert, one truth comes up again and again: people need a decent place to live and work. Traditional housing takes too long and costs too much. That’s where modular camp buildings—especially semi-permanent ones—step in.

Understanding Semi-Permanent Modular Camp Buildings

What defines a semi-permanent modular camp building

Semi-permanent modular camp buildings sit right between temporary shelters and fully permanent complexes. They are built in factories as standardized modules and shipped flat or pre-assembled to the project site. Unlike simple portable cabins, they’re sturdy enough to stay in place for years, yet flexible enough to be dismantled and moved when the project shifts. Think of them as “durable but not forever.”

How modular design differs from traditional construction

With traditional builds, everything happens on site—cement mixers, piles of sand, cranes, hundreds of workers. It’s messy, it’s slow, and delays are almost expected. Modular design flips this: 70–80% of the work happens in controlled factory conditions. At GS Housing’s facilities across China, modules are produced with integrated wiring, plumbing. Once shipped, installation teams can assemble them in days instead of months. That time difference matters when you’re paying daily wages for thousands of workers waiting on housing.

Comparing Semi-Permanent and Permanent Modular Options

What factors determine long-term suitability

Permanent modular camp buildings are great for projects that will last decades—like universities, hospitals, or government facilities. But in many industries, it’s hard to predict future needs. If the mining site dries up or if oil exploration shifts, permanent structures can become stranded assets. Semi-permanent solutions hit the sweet spot: strong enough to last 20 years, but not a financial burden if relocation is needed.

How cost and return on investment are influenced

Costs vary depending on layout, finishing, and logistics. A permanent complex may deliver strong ROI over thirty years, but it requires heavy upfront spending and lengthy permitting. A semi-permanent modular camp spreads costs more evenly. GS Housing’s flat packed container houses, for example, reduce concrete waste by 60% and cut site labor by half. That means faster ROI—even if the camp is only in use for five to ten years.

When flexibility outweighs permanence in remote projects

Consider a pipeline project that stretches across 3,000 kilometers. Camps have to move as construction moves. In this situation, flexibility is not optional—it’s survival. Semi-permanent modular camps can be relocated along the route, saving companies from repeatedly investing in new housing infrastructure. That’s something no permanent camp can offer.

Why GS Housing Leads in Modular Camp Solutions

How GS Housing built global expertise since 2001

Founded in 2001 and headquartered in Foshan, GS Housing is not a newcomer. Over the past two decades, the company has delivered more than 2,000 projects worldwide, from emergency medical stations in China to mega camps in Saudi Arabia’s NEOM project. Their footprint is backed by six factories across China, covering 500,000 square meters with an annual production of 200,000 modular units.

What sets GS Housing production capacity apart

Factories in Guangdong, Jiangsu, Sichuan, Tianjin, and Liaoning operate like assembly lines for buildings. Automated composite panel production, CNC flame cutting machines, graphene powder coating workshops—this level of industrial capacity is rare in modular housing. It means GS Housing can take on both small humanitarian shelters and 10,000-person mega camps without breaking stride.

Why international clients trust GS Housing for mega projects

It’s not just about numbers. It’s about reliability. When GS Housing delivered 4,480 flat packed units for NEOM in Saudi Arabia, the project included not only accommodation but also mosques, canteens, gyms, and offices. The camp was built in record time under desert conditions. That kind of experience reassures oil majors, governments, and NGOs that GS Housing can handle pressure.

Highlighting Multi-Functional Flat Packed Container Houses

How GS Housing delivers quality, safety, and durability

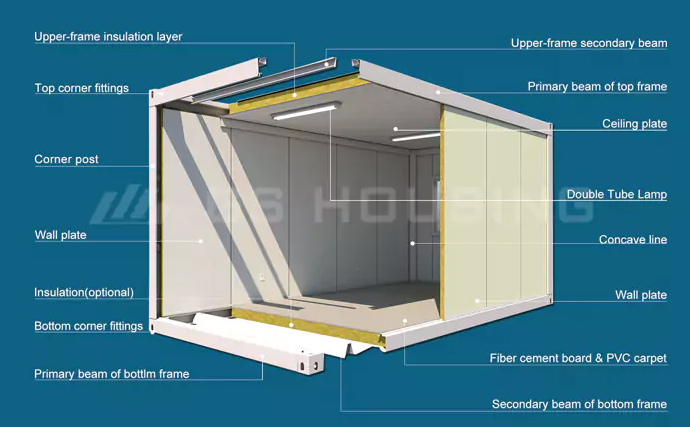

Each module uses steel with anti-corrosion coating and fireproof insulation panels. Testing shows resilience against magnitude 8 earthquakes and wind loads up to 12 on the Beaufort scale. In plain language: they don’t rattle in storms. With a service life of 20 years, these houses are built to be semi-permanent but with the strength of permanent solutions.

Why this product is ideal for semi-permanent camp solutions

For remote projects, speed matters. A flat packed container house can be shipped globally, unloaded, and assembled with minimal tools. For instance, GS Housing teams have completed 830 units for the Guangzhou “Light Project” in just 13 days. That kind of turnaround is why industries under deadline—oil, gas, rail—choose this model.

Benefits for Remote Sites and Harsh Environments

How quick installation saves time in remote projects

In remote areas, delays don’t just cost money—they strain morale. Workers without proper housing can’t perform. Semi-permanent modular camps cut build times by 50% compared to traditional sites. While others are still pouring foundations, GS Housing teams can have beds, and showers ready.

Why mobility and easy relocation matter in field operations

Unlike heavy concrete structures, GS Housing’s modular units can be disassembled, flat-packed, and moved by truck, train, or ship. No need to waste investment when the project shifts. Some clients even move entire office units intact, saving setup time at the new location.

What environmental advantages modular design brings

Construction waste accounts for 30% of landfill globally. By moving most work to factories, modular camps cut site waste by 70%. Less dust, less concrete slurry, fewer noisy machines. And because modules use recyclable steel, they fit well with ESG goals many companies now must report on.

Practical Applications of GS Housing Camp Buildings

How mining and energy projects use semi-permanent camps

In Chile and Mongolia, mining firms deploy modular housing for thousands of workers. GS Housing supplies not just dormitories but also industrial laundries, and medical clinics. Camps are designed to withstand cold winters or desert heat while keeping operations smooth.

Making the Smarter Choice for Your Project

Why semi-permanent modular camps balance cost and flexibility

Not every project needs a thirty-year building. For many, the balance is clear: lower upfront costs, high-quality housing, and the ability to relocate. That’s why semi-permanent solutions are becoming the standard in energy, mining, and infrastructure.

How GS Housing solutions adapt to changing project needs

Need more capacity? Add another row of units. Looking for a place to have fun? Stack and combine modules into a gym or an exhibition hall. As projects scale up or down, GS Housing camps adjust without starting from scratch.

FAQs

- How long can semi-permanent modular camp buildings last?

GS Housing designs its flat packed container houses with a service life of 20 years or more, making them suitable for long projects without committing to permanent concrete structures. - Can modular camps handle extreme weather?

Yes. The structures are tested for seismic resistance up to magnitude 8 and wind loads up to level 12. From deserts to high-altitude plateaus, these camps are built for tough environments. - Are modular camps only for worker housing?

Not at all. GS Housing modular units can be configured into offices, clinics, prayer rooms, classrooms, or even gyms. Entire communities can be built using the same modular system.