How Modular Integrated Construction (MIC) Differs From Traditional Modular Building Construction (MBC) Approaches

How Modular Integrated Construction (MIC) Differs From Traditional Modular Building Construction (MBC) Approaches

Modular Integrated Construction (MIC) redefines Traditional Modular Building Construction (MBC) with unmatched agility, accuracy, and eco-conscious flair. By weaving design, fabrication, and assembly into controlled factory environments, MIC trims project timelines by up to 50%. It also curbs waste and crafts tailored solutions for structures ranging from cozy homes to vast medical complexes. MBC, in contrast, often struggles with uneven quality and rigid design limits due to on-site assembly. GSMOD pioneers this shift with cutting-edge MIC systems, harnessing Building Information Modeling (BIM) and digital tools for seamless project harmony.

Overview of Modular Integrated Construction (MIC)

What is Modular Integrated Construction

Modular Integrated Construction (MIC) is a game-changing strategy in the construction world. It focuses on crafting prefabricated modules with meticulous care. These modules are designed, built, and assembled in controlled factory settings before being whisked to the construction site for final integration. This approach marries advanced manufacturing finesse with contemporary building practices. Its goal? To streamline workflows and boost productivity with unwavering precision.

Key Features of MIC Compared to Traditional Methods

MIC shines with its seamless integration and pinpoint accuracy. Unlike traditional construction, which leans heavily on labor-intensive on-site work, MIC thrives in factory-controlled environments. Here, standardized modules are crafted to meet rigorous quality benchmarks. These modules slot together effortlessly at the site. The outcome is less material waste, sharper quality control, and swifter project completion.

Advantages of MIC in Modern Construction Practices

MIC brings a treasure trove of benefits. It trims construction timelines dramatically. It also curtails costs and champions sustainability. By shifting much of the work to factories, MIC sidesteps disruptions from weather or other external hiccups. Plus, it embraces green practices, cutting waste and optimizing resources with elegant efficiency.

These strengths set the stage for understanding how MIC diverges from its predecessor, Traditional Modular Building Construction.

Understanding Traditional Modular Building Construction (MBC)

Characteristics of Traditional MBC Approaches

Traditional Modular Building Construction (MBC) involves piecing together prefabricated components or sections on-site. It shares a kinship with MIC through prefabrication. Yet, MBC often lacks the same level of precision and integration. Its reliance on manual on-site assembly can stretch project timelines, making it less nimble than MIC.

Common Applications of Traditional MBC

MBC has long been a go-to for temporary housing, portable classrooms, and modular offices. Its flexibility makes it a practical choice for projects where speed and affordability take center stage.

Limitations and Challenges in Traditional MBC

MBC faces hurdles like restricted design freedom and uneven quality due to on-site assembly. Coordinating off-site production with on-site installation can also spark delays or inflate costs, posing persistent challenges.

With MBC’s constraints in mind, let’s explore how MIC stands apart, offering a bolder vision for construction.

Key Differences Between MIC and Traditional MBC Approaches

MIC achieves superior efficiency through fully integrated prefabrication and digital coordination, eliminating the workflow redundancies found in traditional MBC approaches.

Integration and Process Efficiency

Prefabrication vs. Full Integration in MIC

Both MIC and MBC embrace prefabrication, but MIC elevates it to an art form. It synchronizes every stage—design, fabrication, transport, and assembly—for peak efficiency. This full integration sets MIC apart from MBC’s more fragmented approach.

Streamlined Workflow in MIC Compared to MBC

MIC’s workflow glides smoothly, eliminating redundancies that plague MBC. By harnessing digital tools like Building Information Modeling (BIM), MIC ensures precise alignment across all project phases. This harmony translates to faster, more reliable results.

Design Flexibility and Customization

Adapting Design with MIC’s Modular Systems

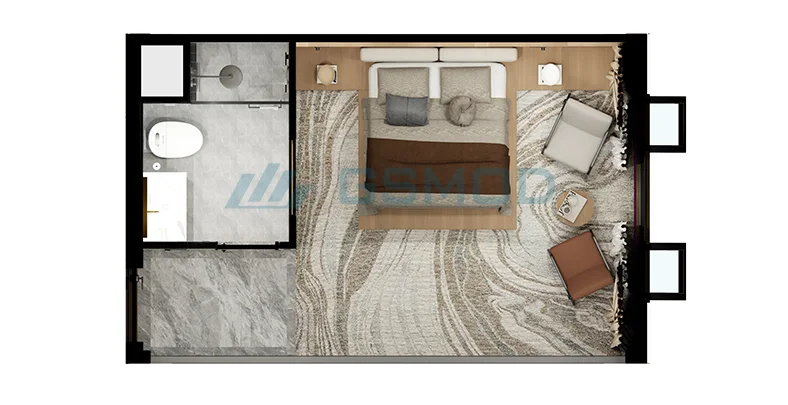

MIC’s modular systems offer boundless creative freedom. Architects and engineers can tailor solutions to fit unique project needs, from homes to hospitals, schools to cultural venues. This versatility makes MIC a chameleon in the construction world.

Limitations in Customization with Traditional MBC

MBC, however, often wrestles with design constraints. Its standardized modules may demand extensive tweaks during assembly, curbing creative possibilities and adding complexity.

Project Timeline and Cost Implications

Time-Saving Benefits of MIC

MIC slashes project timelines with breathtaking speed. By overlapping factory production with on-site prep, it can wrap up projects up to 50% faster than traditional methods. This swift pace is a game-changer for developers.

Cost Optimization Through MIC vs. MBC

MIC also trims costs with finesse. Its factory-controlled setting minimizes material waste while upholding consistent quality. Shorter timelines mean lower labor expenses and quicker returns for developers, making MIC a financial win.

GSMOD’s innovative MIC solutions bring these advantages to life, offering tailored products for everything from residences to commercial hubs, all while upholding exceptional quality.

The Role of GSMOD Products in Promoting Modular Integrated Construction

GSMOD drives innovation in Modular Integrated Construction through precision-engineered prefabricated components manufactured in controlled environments, ensuring quality and minimizing waste. Their systems integrate BIM and digital tools to optimize workflows across all project phases, delivering efficient coordination and accelerated timelines. By offering customizable solutions with consistent quality, GSMOD effectively bridges the gap between traditional MBC and advanced MIC, enabling a seamless transition to more efficient construction methodologies.

What Are GSMOD’s Innovative Solutions for MIC Projects?

Advanced Prefabricated Components by GSMOD

Modular Integrated Construction thrives on precision, and GSMOD delivers with its expertly crafted prefabricated components. These modules are forged in controlled factory environments, adhering to stringent quality standards. Advanced manufacturing techniques ensure seamless on-site assembly. This approach curbs material waste and boosts project durability. From homes to hospitals, GSMOD’s components serve a wide array of needs with unwavering reliability.

Enhancing Efficiency with GSMOD’s Modular Systems

Efficiency is MIC’s heartbeat, and GSMOD amplifies it. Their modular systems, infused with Building Information Modeling (BIM) and digital tools, streamline every project phase. This eliminates redundancies, ensuring flawless coordination between design, production, transport, and assembly. The result? Shorter timelines and consistently high-quality outcomes.

How Does GSMOD Support Transition from Traditional MBC to MIC?

Shifting from MBC to MIC requires overcoming design and quality hurdles. GSMOD leads the charge with fully integrated modular solutions. Their systems offer unmatched adaptability, letting designers customize with ease. Factory-controlled production ensures consistent quality, tackling MBC’s shortcomings head-on. GSMOD’s approach makes the leap to MIC smooth and rewarding.

Future Trends in Modular Integrated Construction

What Emerging Technologies Are Shaping MIC Development?

MIC’s future sparkles with innovation. Robotics and artificial intelligence are redefining how modules are designed and built. AI, in particular, sharpens workflows with predictive analytics, guiding smarter decisions and smoother operations.

What Is the Potential Impact on the Global Construction Industry?

MIC’s rise promises to reshape construction worldwide. It tackles labor shortages and environmental concerns with finesse. By cutting timelines and waste, MIC champions sustainability and affordability. Its versatility suits urban housing, infrastructure, and beyond, expanding its global reach and influence.

FAQs

Q1. How does Modular Integrated Construction differ from Traditional MBC?

A: MIC weaves together all construction stages with precision, while MBC leans on manual on-site assembly, which can be less efficient.

Q2. Can Modular Integrated Construction be used for retrofitting existing buildings?

A: Absolutely. Many modular systems mesh seamlessly with existing structures, enabling swift retrofitting without major demolition.

Q3. What types of projects benefit most from using MIC?

A: Projects needing quick delivery or facing tough environmental conditions thrive with MIC, thanks to its off-site manufacturing prowess.