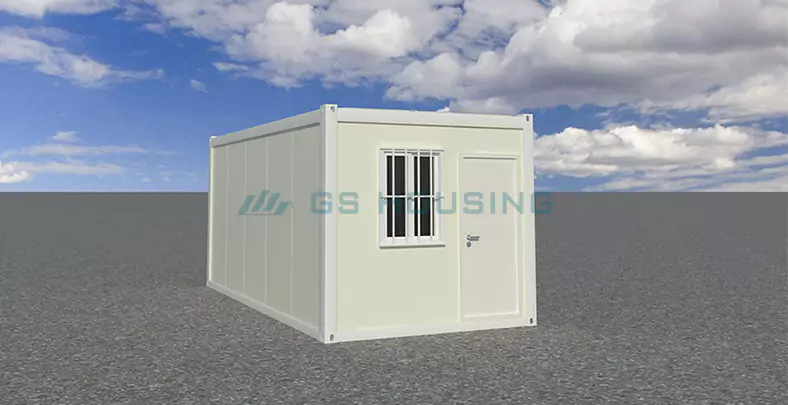

- GS Housing’s Flat-packed container houses feature a high-strength steel structure, enabling quick assembly. Eco-friendly and customizable, these prefabricated units are ideal for pop-up homes, offices, or emergency shelters. If you want to know more details, please click the blue "learn more" button on the right.

- Tailored to your project – choose from flexible layouts, and sizes, all with the speed and efficiency of modular container house steel construction.

- Certifications: ISO / CE / ASTM / SGS / SASO / GOST-R / UL / BUREAU VERITAS

Steel structure products are mainly made of steel, which is one of the main types of building structures. Steel is characterized by high strength, light weight, good overall rigidity and strong deformation capacity, so it is particularly suitable for building long-span, ultra-high and ultra-heavy buildings; The material has good plasticity and toughness, can have large deformation, and can well bear dynamic load; Short construction period; It has a high degree of industrialization and can carry out professional production with a high degree of mechanization.

|

|

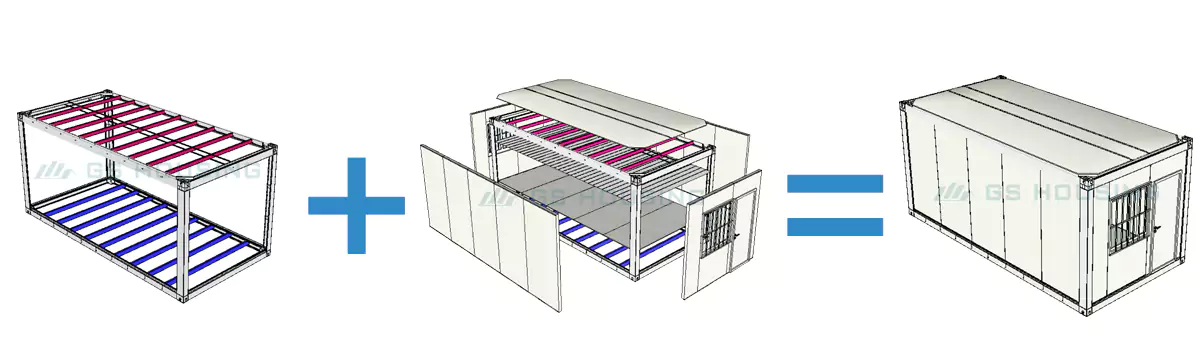

Product Structure: Flat-pack container houses consist of upper frame members, lower frame members, columns, and multiple interchangeable wall panels. The upper frame and columns, as well as the columns and lower frame, are connected using 24 sets of high-strength M12 grade 8.8 bolts, forming an integrated frame structure that ensures stability. This product can be used individually or combined horizontally and vertically to create spacious layouts. The structure is made of cold-formed galvanized steel, with non-combustible materials used for cladding and insulation. Water, heating, electrical systems, and interior finishes are all prefabricated in the factory, eliminating the need for secondary construction—simply assemble on-site and the unit is ready for occupancy.

|

|

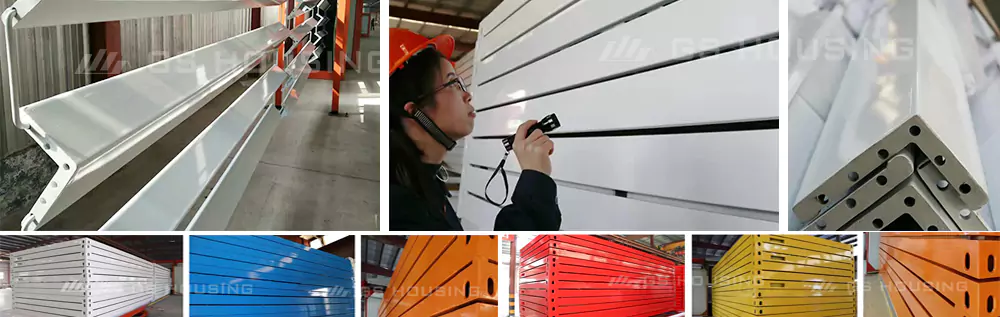

“Graphene Powder Coating: 30-Year Color, Self-Cleaning & Ultra-Durable” Featuring revolutionary graphene pigmentation technology, our GS Housing series comes with a standard Ivory White finish (custom colors available), offering exceptional benefits:

|

|

|

|

Advanced Graphene Powder Coating Technology:

|

||

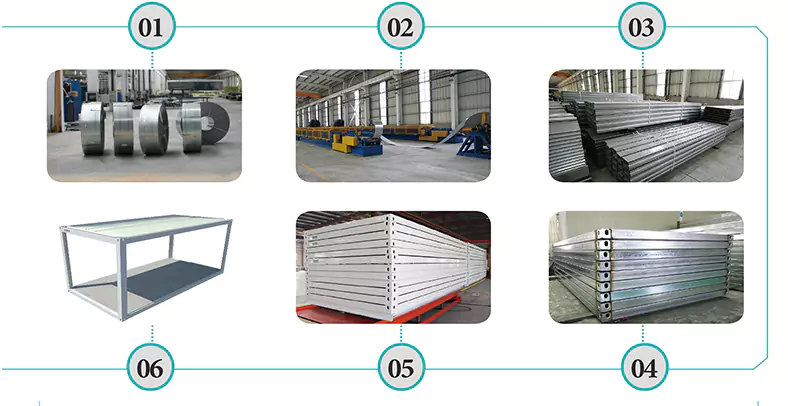

Manufacturing Process: Container House FrameThe raw material (galvanized steel strip) is processed through programmed machinery and pressed by a forming machine to produce the top frame with crossbeams, bottom frame with crossbeams, and columns. These components are then polished and welded to form the complete top and bottom frames. The galvanized components have a zinc coating thickness of ≥1010μm and a zinc content of ≥100g/m³. |

|

| Product Advantages |

| Standard modular house specifiction | ||

| Specifiction | L*W*H(mm) |

Outer size 6055*2990/2435*2896 customzied size could be provided |

| Roof type | Flat roof with four internal drain-pipes (Drain-pipe cross size:40*80mm) | |

| Storey | ≤3 | |

| Design date | Designed service life | 20 years |

| Floor live load | 2.0KN/㎡ | |

| Roof live load | 0.5KN/㎡ | |

| Weather load | 0.6KN/㎡ | |

| Sersmic | 8 degree | |

| Structure | Column | Specification:210*150mm,Galvanized cold roll steel, t=3.0mm Material: SGC440 |

| Roof main beam | Specification:180mm,Galvanized cold roll steel, t=3.0mm Material: SGC440 | |

| Floor main beam | Specification:160mm,Galvanized cold roll steel, t=3.5mm Material: SGC440 | |

| Roof sub beam | Specification:C100*40*12*2.0*7PCS,Galvanized cold roll C steel, t=2.0mm Material:Q345B | |

| Floor sub beam | Specification:120*50*2.0*9pcs,”TT”shape pressed steel, t=2.0mm Material:Q345B | |

| Paint | Powder electrostatic spraying lacquer≥80μm | |

| Roof | Roof panel | 0.5mm Zn-Al coated colorful steel sheet, white-gray |

| Insulation material | 100mm glass wool with single Al foil. density ≥14kg/m³, Class A Non-combustible | |

| Ceiling | V-193 0.5mm pressed Zn-Al coated colorful steel sheet, hidden nail, white-gray | |

| Floor | Floor surface | 2.0mm PVC board, light gray |

| Base | 19mm cement fiber board, density≥1.3g/cm³ | |

| Insulation(optional) | Moisture-proof plastic film | |

| Bottom sealing plate | 0.3mm Zn-Al coated board | |

| Wall | Thickness | 75mm thick colorful steel sandwich plate; Outer plate:0.5mm orange peel aluminum plated zinc colorful steel plate, ivory white, PE coating; Inner plate:0.5mm aluminum-zinc plated pure plate of color steel, white gray, PE coating; Adopt “S” type plug interface to eliminate the effect of cold and hot bridge |

| Insulation material | rock wool, density≥100kg/m³, Class A Non-combustible | |

| Door | Specification(mm) | W*H=840*2035mm |

| Material | Steel | |

| Window | Specification(mm) | Front window:W*H=1150*1100/800*1100,Back window:WXH=1150*1100/800*1100; |

| Frame material | Pastic steel, 80S, With anti-theft rod, screen window | |

| Glass | 4mm+9A+4mm double glass | |

| Electrical | Voltage | 220V~250V / 100V~130V |

| Wire | Main wire:6㎡, AC wire:4.0㎡,socket wire:2.5㎡,light switch wire:1.5㎡ | |

| Breaker | Miniature circuit breaker | |

| Lighting | Double tube lamps,30W | |

| Socket | 4pcs 5 holes socket 10A, 1pcs 3 holes AC socket 16A, 1pcs single connection plane switch 10A, (EU /US ..standard) | |

| Decoration | Top and column decorate part | 0.6mm Zn-Al coated color steel sheet, white-gray |

| Skiting | 0.6mm Zn-Al coated color steel skirting, white-grey | |

| Adopt standard construction, the equipment and fittings are accord with national standard. as well as, customized size and related facilities can be provided according to your needs. | ||

For more information, you can contact us.

| Internal Configuration |

|

|

|

|

| Meeting Rooms | Negotiation Rooms | Offices | Worker Dormitories |

|

|

|

|

| Bathroom | Shower room | Staircase units | Walkway units |

|

|

|

|

| Security Booth | Dining Hall | Recreation Room | Food & Beverage Bar |

| Application Scenarios |

|

|

|

|

| Engineering Camp | Municipal Buildings | Public Service Facilities | Workshop Complex Building |

|

|

|

|

| Military Barracks | Disaster area resettlement | Commercial property |

Tourist Accommodation |

For more information, you can contact us.

| Why Choose GS Housing |

| Authorative Certification |

| After-sales Service | |

| 1 | Do you provide on-site installation service? We provide very detailed installation instruction drawings and videos for every project.For large projects, we will have both installation workers and supervisors on site.The fee for the on-site service should be negotiated with clients. |

| 2 | What’s your delivery time? Normally, delivery time is 7-10 days after deposit received. For large order, the delivery time should be negotiated. |

| 3 | How to control the quality of your product? 1. quality of the design: think about possible problems in advance and provide a high-quality design solution. 2. quality of the raw material: choose the qualified raw material 3. quality of the production: precise manufacturing technique, experienced workers, strict qualit inspection. |

| 4 | How to deal with quality problems? Warranty is 1 years. Within the warranty period, GS Housing will responsible for all quality problems caused by our production. |

| 5 | If there is a clear service life of your products? If have,how long? Under conventional climate and environment, the service life of container house steel frame is 20 years |

| 6 | What designs do you have in different climates (How can the products adopt to different climates)? Strong wind region: improve the wind-resisting ability of the internal structure. Cold region: increase the thickness of the wall,or use good insulation material, improve anti-pressure ability of the structure. High corrosion region: use corrosion resistant material, or paint anti-corrosive coating. |

Leave Your Message

For more information, please fill out the form, and we will respond to you via email within 24 hours.