Container House Factory: How Modular Housing Is Manufactured for Harsh Environments

Container House Factory: How Modular Housing Is Manufactured for Harsh Environments

Introduction: What Is a Container House Factory, Really?

That means every wall, every beam, every cable route is defined before the first piece of steel is cut.

No weather delays.

No on-site improvisation.

No last-minute decisions.

This factory-first approach is exactly why modular systems are widely used for prefabricated site accommodation, worker camps, and remote industrial projects. It reduces uncertainty. And in engineering, uncertainty is cost.

Companhias como GS Housing design their entire workflow around this logic. Not because it sounds good in brochures, but because controlled environments produce controlled results.

Raw Materials and Steel Structure Fabrication

Everything starts with the frame.

Not decoration.

Not interior.

Steel.

- CNC cutting

- Precision bending

- Jig-positioned welding

- Full anti-corrosion treatment

This is not manual guesswork.

Frames are fixed in position before welding starts. That means alignment is locked, not adjusted later.

It’s like using a mold instead of freehand drawing.

If the mold is right, every piece is right.

After welding, the structure goes through:

Weld seam inspection

Grinding and smoothing

Hot-dip galvanizing or zinc coating checks

This matters, especially for coastal projects, desert sites, and high-humidity regions, where corrosion does not wait.

A weak frame will not fail immediately.

It fails slowly.

And slowly is expensive.

This is why reliable modular container house manufacturing always puts structural accuracy first.

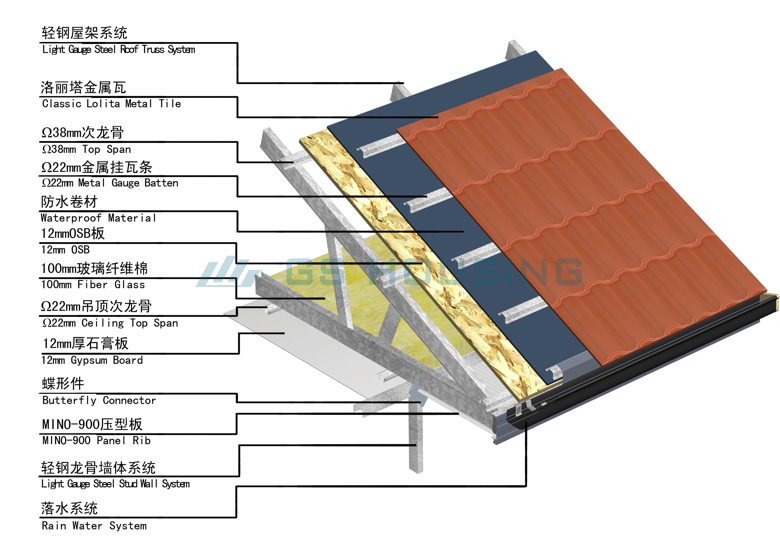

Wall Panels, Insulation, and Roofing Systems

Once the skeleton is complete, the building needs skin.

In a professional prefabricated container house factory, wall panels are not cut on site. They are produced as finished components.

Typical process:

1、Outer steel sheet roll-formed

2、Insulation layer inserted (rock wool or PU)

3、Inner skin bonded

4、Edges sealed under pressure

This creates a rigid sandwich panel.

Not stylish.

Just effective.

Rock wool is often used in factory-built worker accommodation because it resists fire and doesn’t absorb moisture.

PU is chosen when thermal performance is critical.

Roof systems follow the same logic.

Better factories do not simply place sheets on top. They design:

- Integrated drainage channels

- Sloped water flow paths

- Multi-layer waterproof systems

Water is lazy.

If you don’t guide it, it stays.

If it stays, it leaks.

That’s why in many prefabricated modular housing solutions, the roof is treated as a system, not a cover.

Electrical & Plumbing Pre-installation in Factory

This is where factory production really shows its strength.

On-site wiring is messy.

On-site plumbing is risky.

Inside a controlled container house production process, electrical and plumbing systems are installed before walls are closed.

Workflow usually looks like this:

- Cable trays fixed into frames

- Wires pulled, labeled, and tested

- Sockets and switches mounted

- Water pipes installed and pressure-tested

- Drainage pipes connected and sealed

All before panels are closed.

Think of it like building a car dashboard before closing the body.

You see everything.

You reach everything.

You fix everything.

Para remote mining site modular camps or infrastructure worker housing, this reduces on-site chaos dramatically.

Less rework.

Fewer mistakes.

Faster installation.

Quality Control and Factory Testing

Quality control is not one step.

It is many small steps.

In a real container house factory, inspections happen:

- After frame welding

- After panel installation

- After wiring

- After plumbing

- After full assembly

Each stage has its own checklist.

Not memory.

Not experience.

Checklists.

Because people forget.

Processes don’t.

Typical checks include:

- Structural alignment

- Weld seam integrity

- Coating thickness

- Electrical continuity

- Water pressure stability

- Door and window sealing

This is not exciting work.

But it is the difference between a unit that lasts 5 years and one that lasts 15.

This discipline is one of the reasons established suppliers like GS Housing’s container camp systems are frequently used in large-scale worker accommodation projects.

Packing and Transportation Methods

After inspection, the unit is prepared for transport.

This is not just plastic wrap.

Professional packing includes:

- Corner protection

- Film wrapping

- Steel frames for stacking (if needed)

- Clear lifting point marking

Why so careful?

Because transport is rough.

Ships move.

Trucks shake.

Cranes are not gentle.

A responsible container house manufacturer designs with transport in mind from the beginning.

Some projects require:

Fully assembled modules

Flat-pack systems

Foldable structures

Each has its place.

Flat pack saves space.

Assembled saves time.

Foldable balances both.

For overseas delivery and prefabricated worker camps in extreme climates, logistics planning is part of product design, not an afterthought.

Why Factory Production Ensures Stable Quality

Traditional construction depends on:

- Weather

- Site conditions

- Worker skill

- Material delivery timing

- Factory production depends on:

- Machines

- Procedures

- Training

- Control systems

One is variable.

The other is stable.

In modular container house manufacturing, stability is everything.

Same steel.

Same jigs.

Same process.

Day after day.

It’s the difference between cooking on a campfire and cooking in a kitchen.

Both make food.

Only one makes the same dish every time.

That’s why many project owners choose factory-built container homes for worker accommodation instead of site-built temporary shelters. Not because they look better, but because they behave better.

Real Project: Saudi Red Sea Container Camp for 2,500 Workers

A good example is the Saudi Red Sea container camp project for 2,500 workers, supplied as modular units for a large coastal industrial development.

This site faces:

- Extreme heat

- High UV radiation

- Dry desert winds

- Heavy sand and dust

- Significant day–night temperature difference

Designing for this environment is not about comfort.

It’s about survival of materials.

In this project, the factory design had to address:

Strong UV resistance to prevent panel aging and seal degradation

Enhanced thermal insulation to handle hot days and cooler nights

Reinforced sealing systems to block sand intrusion

High-strength galvanized steel structure to resist long-term deformation

Integrated drainage design despite low rainfall, because when desert rain comes, it comes fast

These details were built in at the factory stage, not adjusted on site.

Because in the desert, you don’t get second chances.

This kind of environment is exactly where controlled prefabricated container house factory production proves its value. Not in theory. In reality.

Final Thoughts: It’s Manufacturing, Not Improvisation

A modern container house factory is not a warehouse with welding machines.

It is a production system.

A serious container house manufacturer is not selling boxes.

They are managing risk.

And a well-designed steel structure container house is not strong because it looks strong.

It’s strong because it was engineered, tested, and repeated.

From raw steel to finished unit, every step matters.

Every step is controlled.

Every step is predictable.

That is the quiet strength of factory production.

Not loud.

Not flashy.

Just reliable.

If you are planning modular camps, prefabricated site accommodation, or worker housing in high-risk environments, it is usually worth discussing technical details directly with manufacturers who operate their own factories. Teams like GS Housing can often provide practical input on structure, insulation, and logistics long before problems appear on site.

Not to sell.

But to plan properly.

For project owners and contractors planning modular camps, worker accommodation, or container housing in harsh environments, understanding factory capabilities is critical before finalizing a supplier.

Discussing structure design, insulation systems, logistics, and quality control at the early stage often prevents costly adjustments later.

If you want to understand how a container house factory can support your specific project requirements, GS Housing’s technical team can walk you through manufacturing options, delivery methods, and project planning considerations.

Anterior:Sustainable Housing Solutions: How Expandable Container Houses Support Large-Scale Projects

Seguinte:Modular Camp Buildings for Construction, Disaster Relief, and Military Use

Conteúdo Relatado

-

Notícias da indústriaGS Housing Modular Classrooms: A Smart, Scalable Solution for Modern Schools

Notícias da indústriaGS Housing Modular Classrooms: A Smart, Scalable Solution for Modern Schools -

-

Notícias da indústriaGS Housing: Redefining Emergency Response with Rapid-Deployment Container Solutions

Notícias da indústriaGS Housing: Redefining Emergency Response with Rapid-Deployment Container Solutions